Position Control Torque Reaction Arm

Optional two-axis or three-axis

The torque arm(350A3/650A3/900A3), integrated with a digital management system(CL-A2/CLA-3), is upgraded to a Position Control Torque Reaction Arm.

By setting data through the production line Key User, the screw hole position and the order of screwing are set according to requirements, and the operator follows the screen display to operate, which greatly reduces the screwing errors caused by unfamiliarity with the operation and effectively regulates the product yield and quality.

TRPC-A2 Series

Position Control Torque Reaction Arm

Torque Reaction Arm working radius max R439mm/R652mm/R900mm(128°) available to choose from.1.Spindle arm is rotatable 360°,And the small arm can also rotate about 325°, wide range of activities. 2.Keep the advantages of Torque Reaction Arm:Protects the wrist from stress, Effortless hanging tools and make sure 90° locked.

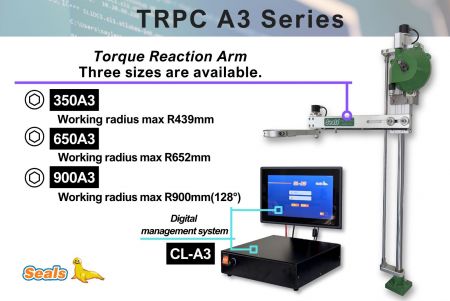

TRPC-A3 Series

Position Control Torque Reaction Arm

It mainly controls the screw locking sequence, ensures the screw locking quantity and the torque of each screw, and monitors, reports and audits when errors and exceptions occur. In addition to maintaining the labor-saving functional advantages of the original torque arm, an industrial PC is selected to perform precise torque control and accurate positioning on the work platform. The personnel completes the operation according to the system prompts to ensure that the screw locking and payment of the product without guide rails is completed. And record the locking parameters of each screw to make all execution processes traceable.