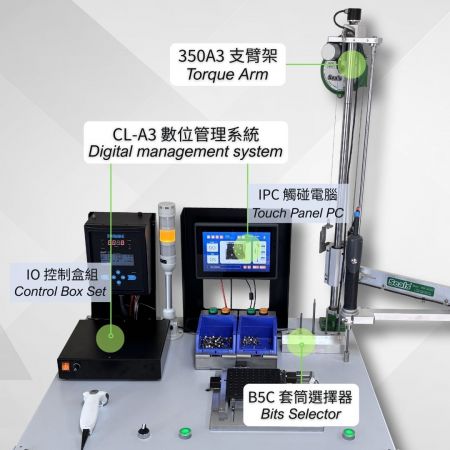

Digital management system

CL-A3

Seals CL-A3 Digital management system, According to the needs of the production line, the order of screws in locking can be monitored, positioning, detection, recording, prompting, counting, Optimize product yield, quality control management.

Match TRPC series Position Control Torque Reaction Arm, In addition to maintaining the original labor-saving function advantages of Torque Arm, an industrial PC was selected.

Execute precise torque control and precise position and sequence positioning on the work platform, The personnel complete the work according to the system prompts to ensure that the product has no missing screws and is assembled. And record the locking parameters of each screw to make all execution processes traceable.

Nickname

touch screen / electric control screen / Intelligent control

✔CL-A3, Allows customization of logical sequences according to needs, Including picture editing, screw parameter editing, input editing, output editing, delay editing and message prompts.

Users can customize the product according to different product and assembly needs, Freely set a series of assembly steps.

For example:Specify the order of screws or display messages to alert operators at specific steps, Input and output means that other devices or sensors can be connected to make the system more flexible.

✔CL-A3, Not only a sequence and control system, it can also be an automation device that manages workstations on the assembly line.

Its functionality is not limited to controlling assembly sequences and preventing errors; it can also integrate other system functions.

For example:Screw selection system, driver bit selection system, vision system, etc. Make the operation of the entire workstation more automated and intelligent.

Function

➤Powerful functionality:

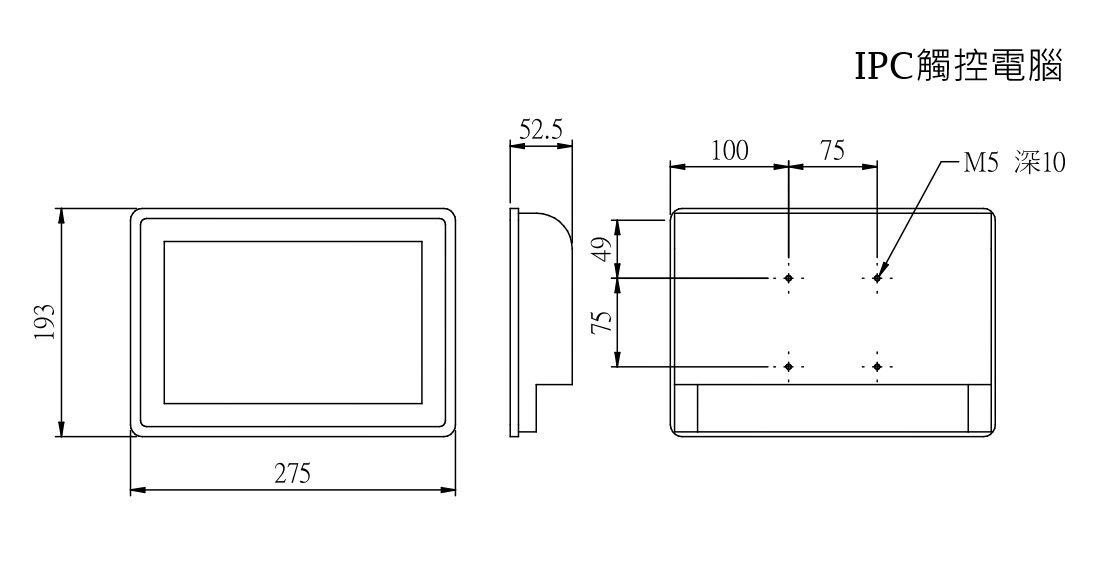

- IPC Touch Built-in operating system

- 10.1 inches IPC Touch touchscreen, quick and easy setup.

- Editable prompt image and loading prompt sound source.

- Can plan up to 100 groups of work items.

- Each group of work can plan 300 processes (locking position/sequence).

- Supports 3-axis coordinate encoder (R1, R2, Z)

→R1、R2 Precise positioning of control plane.

→Z Control screw length and locking height.

➤Extended functions (optional):

- Can integrate various brands of electric screwdrivers with relevant and suitable signals, ervo screwdriver.

- Bit selector.

- Barcode scanner.

- Three color light warning light.

- Multi-purpose sensor SENSOR.

- external control buttons.

- Multifunctional reminder light.

- I/O Module expansion.

➤User optimization features:

- It has authority management to facilitate on-site operations, error reporting, exception review, batch quantity... and other management and monitoring.

- The start switch of the main control system (electric/servo) screwdriver can only open the locking operation that complies with the regulations before the operator can lock it. The rest will be locked and cannot be started.

- It can ensure that personnel can perform screw locking operations according to instructions, rather than relying solely on the desktop, personnel requirements.

- Graphics and sound effects are used to remind the user that the correct position can be locked, the process, locking position, warning... etc., the information is clear at a glance.

- Easy editing of work procedures, visualization of processes and sequences, and operator-guided work procedures.

- Locking position prompts, follow the prompts to complete the screw locking without missing parts.

- Create and modify jobs based on authority. Only operations that comply with the rules can be performed by personnel. Others will be locked and cannot be started.

- The control system provides: user, team leader, manager, and the highest four permissions to assist in on-site operations, error reporting, exception review, batch quantity, etc. management and monitoring.

Applications

- Electric / servo driver set.

- Servo signal motor.

- Torque Reaction Arm.

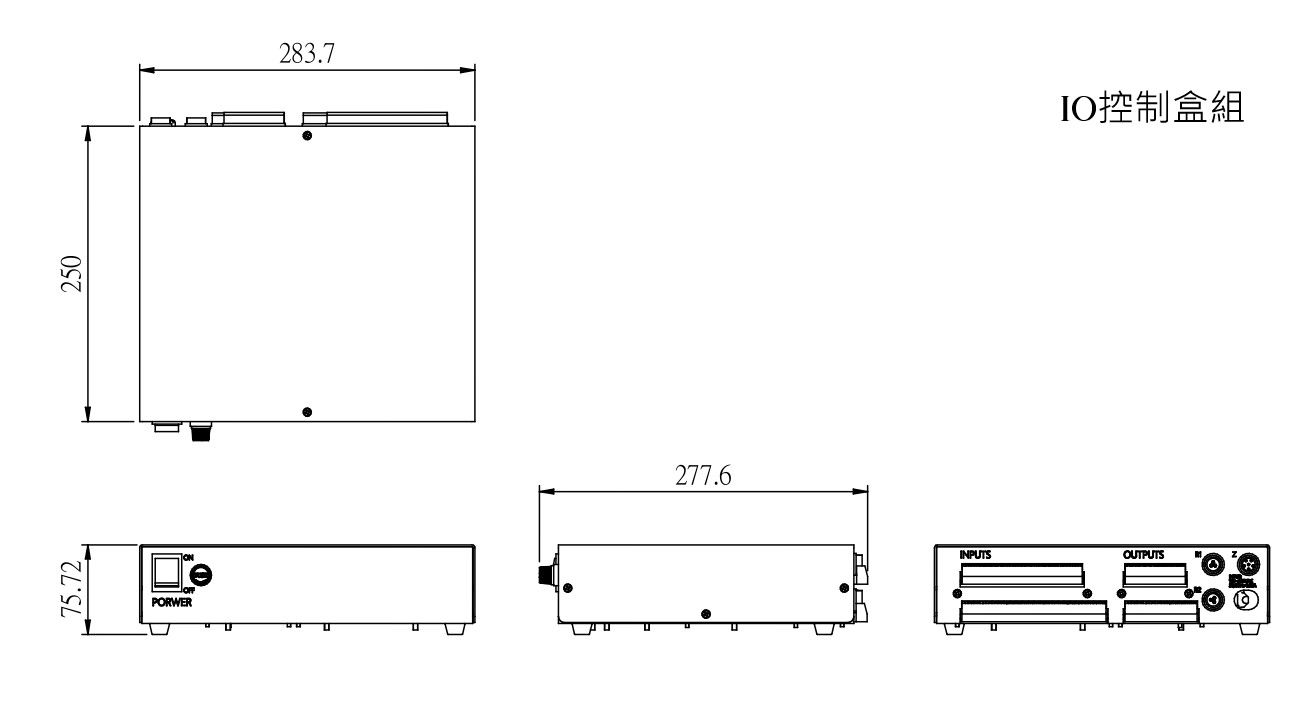

Accessory

- Dimensions

-

- Movies

- Related Products

-

-

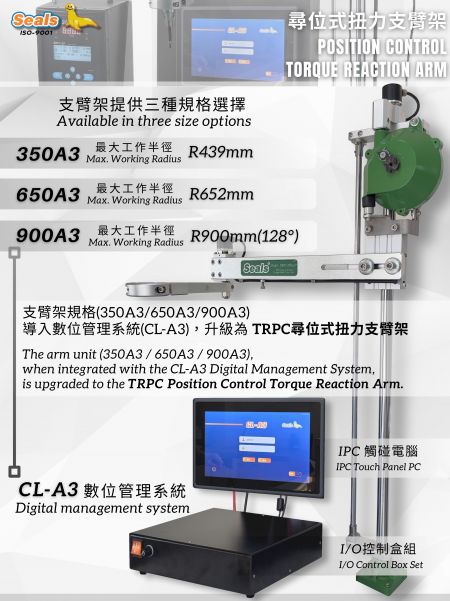

Position Control Torque Reaction Arm-A3(working radius max R439mm)

TRPC-350A3

Seals TPRC-A3 Series Position Control Torque Reaction Arm, Powerful tools for production management, The main control screw lock position sequence, guaranteed quantity And each screw has torque to reach, And monitoring when errors and exceptions occur, Report and Review.

-

Position Control Torque Reaction Arm-A3(working radius max R652mm)

TRPC-650A3

Seals TPRC-A3 Series Position Control Torque Reaction Arm, Powerful tools for production management, The main control screw lock position sequence, guaranteed quantity And each screw has torque to reach, And monitoring when errors and exceptions occur, Report and Review.

-

Position Control Torque Reaction Arm-A3(working radius max R900mm)(128°)

TRPC-900A3

Seals TPRC-A3 Series Position Control Torque Reaction Arm, Powerful tools for production management, The main control screw lock position sequence, guaranteed quantity And each screw has torque to reach, And monitoring when errors and exceptions occur, Report and Review.

-

- Files Download

-