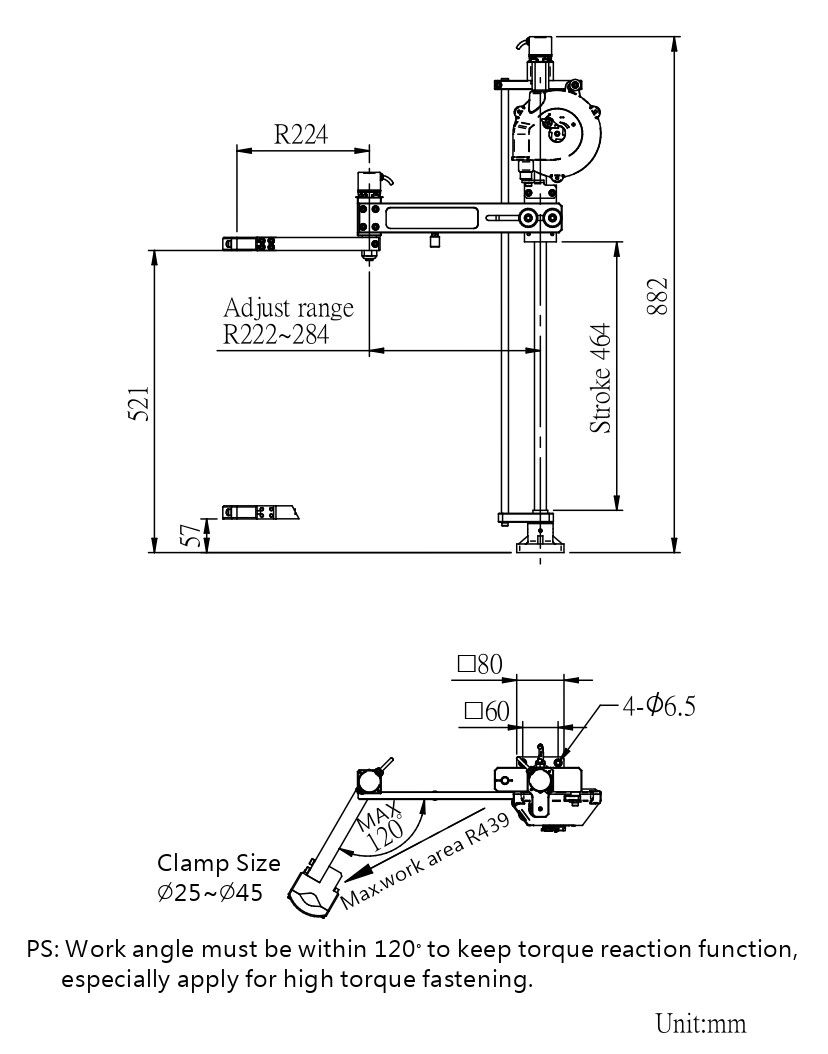

Position Control Torque Reaction Arm-A2(working radius max R439mm)

350A2

Seals TPRC Series

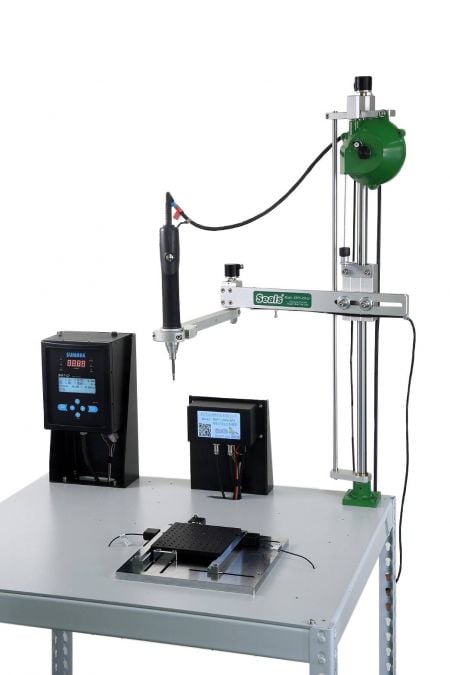

Position Control Torque Reaction Arm, Powerful tools for production management, The main control screw lock position sequence, guaranteed quantity And each screw has torque to reach, And monitoring when errors and exceptions occur, Report and Review.

Nickname

locate / Torque Supporting Arm / Screwdriver Arm

"

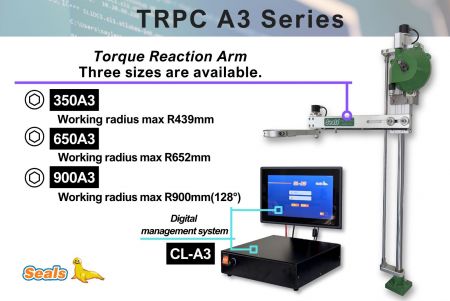

TRPC-350/650/900A2Position Control Torque Reaction ArmmatchCL-A2 Torque Reaction Arm Control BOX,maintain the original Torque Reaction Arm Labor saving function, lock verticality and Stable and not easy to obliquely lock……,In terms of function, there has been a great improvement.

Through the production line Key User setting data,Set the position of the screw hole according to the requirement and sequential locking screws, The operator operates according to the screen display, Significantly reduce lock payment errors caused by unfamiliar operations, Effectively regulate product yield and quality.

"

Function

1.control system master(electric/servo)Start switch for screwdriver, Only lock screw operations that comply with the rules are open, to allow operators to work, The rest are all locked and cannot be started.

2.The control system provides:User, supervisor, administrator three kinds of authority, to assist on-site operations, bug report, Exception review, batch quantity…etc management monitoring.

3.It can ensure that personnel can perform screw locking operations according to instructions, rather than relying solely on the desktop, personnel requirements.

4.Prompt users with icons and sounds, The position is correct to lock the screw.

5.Can integrate various brands of electric screwdrivers with relevant and suitable signals, ervo screwdriver.

6.Spindle arm is rotatable 360°,And the small arm can also rotate about 325°, wide range of activities.

7.Keep the advantages of Torque Reaction Arm:Protects the wrist from stress, Effortless hanging tools and make sure 90°locked.

8.5 inches TFT-LCD color HMI touch screen, Quick and easy setup.

9.Store 30 groups of product points, Each group of products can be defined 32 hole lock order.

10.Support workpiece positioning and start SENSOR.

11.Provides 5 positioning tolerance classes.

12.positioning accuracy:Angle encoder0.09°。

13.Set the positioning tolerance and positioning delay according to the locking screw requirements.

14.Tool requirements:Basic forward/reverse start, torque reach, two signals.

"|

Specification |

Type |

350A2 | 650A2 | 900A2 |

|

Weight (net weight) |

About 7.8KG | About 10.9KG | About 11.4KG | |

|

Maximum Torque Limit |

150 kgfcm(14.7Nm) | 250 kgf-cm(24.5Nm) | 250 kgf-cm(24.5Nm) | |

| Setting place | general indoor | |||

| Voltage | 100-240V AC | |||

|

Working temperature |

0°C ~ 40°C (NO freezing) | |||

| working environment humidity | 20 % ~ 90 % (NO freezing) | |||

Applications

- Electric / servo driver set.

- Automatic screw machine.

Accessory

- Dimensions

-

- Gallerys

- Related Products

-

-

Position Control Torque Reaction Arm-A2(working radius max R652mm)

650A2

Seals TPRC Series Position Control Torque Reaction Arm, Powerful tools for production management, The main control screw lock position sequence, guaranteed quantity And each screw has torque to reach, And monitoring when errors and exceptions occur, Report and Review.

-

Position Control Torque Reaction Arm-A2(working radius max R900mm)(128°)

900A2

Seals TPRC Series Position Control Torque Reaction Arm, Powerful tools for production management, The main control screw lock position sequence, guaranteed quantity And each screw has torque to reach, And monitoring when errors and exceptions occur, Report and Review.

-

Torque Reaction Arm Control BOX

CL-A2

Seals CL-A2 Mainly control the screw locking order, Each screw has torque to reach.

-

C Shaped Table Clamps - Clamp Range : 13.5-75mm

TA-C

C-shaped table clamps are provided as options according to requirements, so that the installation arm frame is not restricted by the table shape, and the C-shaped table clamps can be easily installed on the work table and firmly fixed on any work table. Our company provides two installation methods: upright and C-shaped table clamps. C-shaped table clamps are only suitable for light-torque screwdrivers. For high-torque screwdrivers, it is recommended to stand upright. The "base" of the torque arm frame is directly locked and fixed to a firm On the work table. Desktop C-clamp for torsion arm stand, suitable for the following series: TA-300, TA-600, TR-350, TR-650, TA-300S, TA-600S

-

.jpg?v=d90909ea)