Magnetic Type Automatic Screw Feeding Machine

CM-30M

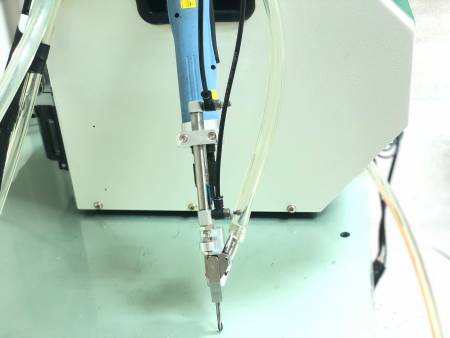

The SEALS CM-30M Magnetic-Type Automatic Screw Feeder is designed to provide high efficiency and precision in handheld screw fastening applications. Utilizing a push-pull jaw mechanism and a magnetically driven bit, the screw is instantly ejected and securely held at the tip, fully exposed for quick and accurate alignment with the screw hole.

This design is especially ideal for challenging environments where traditional jaws cannot reach—such as deep holes, wiring areas, curved surfaces, or tight spaces near walls—enabling precise fastening even under constrained conditions.

The electric screwdriver set features a lever-activated, brushless torque control design, offering high precision, easy torque adjustment, and long-term durability. Without carbon brushes, the driver remains cool during extended use and provides a more comfortable experience for the operator.

The screw feeding unit is built to be rugged and durable, with a simple and compact structure that allows for quick installation and easy adjustment. Most importantly, setup can be completed by a single operator with minimal effort.

Nickname

Hand-held adsorption automatic locking screw machine

Features

1. Screws are instantly ejected after feeding at a speed of 30–40 pcs/min, significantly improving productivity and reducing labor costs.

2. Lightweight screwdriver design reduces operator fatigue.

3. Operates independently or integrates into production lines for enhanced fastening quality and cycle time.

4. Screws are automatically delivered to the bit, eliminating manual screw handling and positioning.

5. Fully exposed screws allow precise alignment; press to fasten, release to feed the next screw—fast and efficient.

6. Average cycle time of 1.5 seconds per screw; enables semi-automation and reduces manpower by 1–2 operators.

7. One-handed operation allows the other hand to stabilize the workpiece for better control.

8. Uses a swing-type feed plate system for low noise, minimal screw wear, and stable feeding performance.

- Related Products

-

-

Robot Type Vacuum Pick-up Automatic Screw Feeder

CM-TABLE-V

The CM-TABLE-V system integrates a Japan-made Quicher screw presenter with a programmable XY desktop robot for automatic vacuum screw pick-up and placement. Screws are lined up and rotated to the vacuum pick-up point, where the nozzle collects and delivers them to each fastening position according to programmed paths. The system is ideal for automated screw fastening where operators only need to load/unload the workpieces, as the robot handles the entire screw fastening cycle. The vacuum nozzle and clamping system can be customized based on screw type and working conditions for consistent, stable operation. Equipped with a brushless torque-controlled screwdriver, the system can detect floating screws, stripped threads, and torque completion, ensuring fastening quality. The belt-driven stepper motor ensures low noise and high positioning accuracy (±0.02mm).

-

Gantry Type XY Table Automatic Screw Fastening Machine

CM-TABLE-GANTRY

The SEALS CM-TABLE-GANTRY is a floor-standing automatic screw fastening system built with a robust gantry structure, featuring dual Y-axis supports and a ball screw-driven XY servo slide table. Compared to single-arm or cantilever robots, this design provides superior repeatability, higher load capacity, and greater structural stability—making it ideal for large-scale assemblies and multi-screw fastening applications. Integrated with SEALS air-blow screw feeding technology, the system delivers screws in as fast as 0.2 seconds per cycle. The high-precision XY servo module shortens travel distances by over 60%, significantly improving production speed and efficiency. Widely used in industries such as automotive components, computer peripherals, and large plastic or metal parts, the SEALS CM-TABLE-GANTRY supports multi-point fastening and can be optionally equipped with safety light curtains for enhanced operator protection.

-

- Files Download

-

-

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.

-