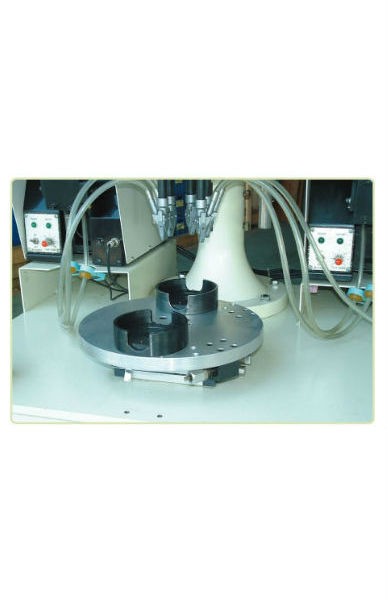

Multi Spindle Automatic Screw Feeding and Fastening Machine

CM-200~CM-800

SEALS CM-200~CM-800 multi-spindle screw fastening machines are customized solutions designed for simultaneous multi-screw operations. This system significantly increases productivity while ensuring fastening consistency and product quality. The rotary table with dual fixtures allows parallel screw fastening and loading/unloading, improving workflow efficiency and operator safety. Integrated with SEALS’ reliable screw feeders and torque-controlled electric screwdrivers, it delivers a high-performance, automated assembly solution.

Nickname

Multi Spindle Automatic Screw Fastening System

Features

1. Simultaneous Multi-Screw Fastening

Enables multiple screws to be tightened at once, significantly boosting production efficiency.

2. Stable and Consistent Quality

Ensures precise and uniform torque application across all screws, improving product quality consistency.

3. Dual-Station Design with Rotary Cylinder

Separates screw fastening and loading/unloading areas for uninterrupted operation and enhanced operator safety.

4. Customizable Screw Layout

Machine dimensions, spindle quantity, and screw hole positions can be customized to fit specific workpieces or production needs.

5. Integrated with SEALS Feeder & Torque-Control Screwdriver

Delivers a complete high-efficiency fastening solution with proven reliability.

6. Supports Full or Semi-Automated Integration

Easily incorporated into existing production lines or configured as a stand-alone station.

7. Time-Saving and Labor-Reducing

Reduces operator workload while maximizing cycle time efficiency.

Function

◆ Increased Productivity:

Simultaneous multi-screw fastening significantly reduces cycle time and boosts production efficiency.

◇ Consistent Quality:

Synchronized fastening ensures uniform torque, preventing loose screws and structural instability.

◆ Simplified Operation:

Compatible with rotary modules and automated loading/unloading systems to save labor and streamline workflows.

◇ Highly Customizable:

Supports multi-station setups, complex geometries, and high-precision fastening tasks to meet diverse application needs.

- Movies

- Related Products

TR-650M Multi-Drive Fastening System with torque reaction arm

TR-650M

SEALS, TR-650M, Multi-Drive Fastening System, increases screw fastening productivity and quality by fastening more than two screws at the same time. By installing two or more screwdrivers in torque reaction arm, TR-650Multi-Driver not only increase efficiency but also enhance fastening balancing. This solves the problem of fastening sequence for multi screws in the sealing cover of container chamber, cylinder, tank, housing, etc. The multi screw is fastening simultaneously so that there will be no problem the first screw cause the gap or relevant issue.By the handling bar, it is easy to aim at the screw holes. Meanwhile, there is a lever trigger in the handling par to control the fastening process. The torque reaction and tool supporting arm TR-650 allow weight less operation experience and flexible aimming movement.

Index Table Automatic Screw Feeder Fastening System

CM-INDEX

SEALS CM-INDEX – Index Table Automatic Screw Fastening System The SEALS CM-INDEX is a high-efficiency rotary indexing screw fastening system designed for multi-station automated assembly. Available in 4, 6, or 8-station configurations, the system allows operators to focus solely on loading and unloading, while the indexing table sequentially completes all fastening tasks.Capable of integrating multiple pneumatic or electric screwdrivers for simultaneous or sequential screwdriving operations, the CM-INDEX ensures consistent workflows, enhanced quality control, and higher output. Adjustable rotation speed and reliable screw feeding mechanisms help reduce manual labor and increase productivity—making it an ideal solution for boosting automation and product value.

Robot Type Automatic Screw Feeder

CM-TABLE

The SEALS CM-TABLE series is a programmable, robot-type automatic screw fastening solution designed to reduce manual labor and improve process consistency. By integrating Japanese JANOME desktop robots with precision screw jaws, torque-controlled electric/pneumatic screwdrivers, and intelligent screw feeding systems, CM-TABLE delivers high-speed, high-precision, and highly repeatable performance, ideal for high-mix, low-volume production environments.Screw fastening points and motion paths can be fully programmed and stored in up to 255 modules (or 30,000 points), allowing rapid changeover and support for flexible production lines. The system supports real-time error detection—including screw shortage, torque achievement, and stripped-thread detection (optional)—to ensure consistent quality and reliable operation.Depending on the application, SEALS offers both belt-driven XY systems with stepper motors and ball-screw-driven models powered by servo motors, providing optimal configuration for speed or precision. A range of working platform sizes (200×200mm to 510×510mm) is available to accommodate various workpiece sizes.With features like data collection, programmable control, and automation readiness, CM-TABLE helps standardize the screw fastening process and ensures high stability, independent of operator influence.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.