Power switch/socket panel Application

【Case question】

The power switch and socket panel require small size and large number of lock screws.

【solution】

1. It provides faster operating speed up to 20~30 screws per minute, reducing processing time.

2. Automatic feeding to completely save the screw picking and moving action.

3. Multiple locks can be paid simultaneously.

| Processing methods | Manual work | Automatic Screw Feeder |

|---|---|---|

| Time efficiency | Grabbing/moving/aligning takes a long time | It provides faster operating speed up to 20~30 screws per minute |

| Product quality | Poor locking, quality cannot be guaranteed | Even torque, no gap in lock |

| Human resources | Need a lot of manual participation to complete | High efficiency, one device replaces multiple manpower |

| Future development | Increasing manpower = increasing costs, which will not be considered by the company | Completely replace manual operations and quickly recover costs |

Seals Automatic Screw Feeder Characteristic

Hand held

- Strong versatility, flexible operation, suitable for variable-point operations.

- It is equipped with Spring Balancer to provide load free operation experience.

- Automatic feeding to completely save the screw picking and moving action.

- The torque-controlled screwdriver is used to improve the fastening quality for the customer.

- Simple structure and easy maintenance.

Two Outlets

- One feeder supply screws for two screwdriver sets independently.

- Speed up to 45 pieses of screws per minute/ per screwdriver set.(Total 90 pcs/min./one machine)

- Simple structure and easy maintenance.

Robot Type Automatic Screw Driving Machine

- Thread-slipping detection and warning functions are included.

- Short supply detection and warning functions are included.

- It can be used to support varied height fastening.

- Different working memory modules can be changed in one minute with Control Panel, which is suitable for small-quantity diversified production.

- It can use remote teaching MDI to write programs;or use the computer for online operation.

- Related Products

-

-

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

-

Automatic Screw Feeder with Lever-Activating screwdriver set

CM-30T

SEALS CM-30T Automatic Screw Feeder adopt ergonomic design of screwdriver set. The operator only need to simply trigger the lever of driver and the bit will push downward and fasten screw automatically. SEALS CM-30T reduces the downward press stroke of operator to enhance the productivity and reduce fatige . Meanwhile, the jaw will not press the surface of work-piece hardly so that it could also protect the coating of products. For automation purpose, SEALS automatic screw feeder also could be integrated into automation machine such as XY Table, SCARA robot, 6 axis ROBOT and any customized auto assembly machine, etc. And, its automation version also can provide relevant signals and receive control signal for communicate with major control system.

-

Vibration Bowl Type Automatic Screw Feeder for Two Screwdriver Sets

CM-502

SEALS CM-502 Vibration bowl type automatic screw feeder supply screws for two screwdriver sets independently. SEALS CM-502 allows two operators with different screw consumption speed. For each screwdriver set, it could speed up to 45 pcs screw per minute. This could much reduce the unit cost. SEALS CM-502 could design for screw size from M1.0 to M8 and screw length up to 30 mm. It is easy to maintenance due to its simple structure. Due to the tank, it could load more screw than sword type automatic screw feeder.

-

Robot Type Double Y Vacuum Pick-up Automatic Screw Feeder

CM-TABLE-V-2Y

Desktop robot type - double Y vacuum pick-up automatic screw fastening machine, using four-axis controller, easy to operate, stable performance, suitable for mobile phones, POS machines, walkie-talkies, tablet computers, hardware parts assembly, circuit board assembly, etc. Suitable for lightweight, small size parts and product assembly. Your best choose to replace the traditional manual handling of the screw with a vacuum suction screw and a fast-moving XY TALBE. The double Y stage allows the operator to load and unload the work-piece in one stage and the machine fastening screw in another stage at the same time. Chengmao double Y vacuum pick-up automatic screw fastening machine achieves continuous uninterrupted work to improve screw assembly efficiency. The operator can loading the material on another worktable, which is safe, convenient, time-saving and labor-saving.

-

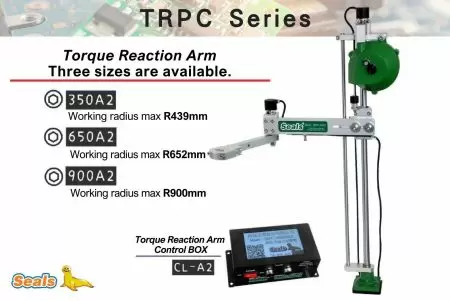

Torque Linear Arm ( 594mm horizontal Stroke)

TA-600

Seals Torque Reaction Arm designed to avoid for injuries caused by repetitive work and overusing the arm can occur in daily work activities. We provide the opportunity to implement ergonomic improvements to the manufacturing process. This torque reaction arm removes torque twisting and weight loading to create a safe work environment.

-